New Post

Maya

16 mins read

Maya

16 mins read

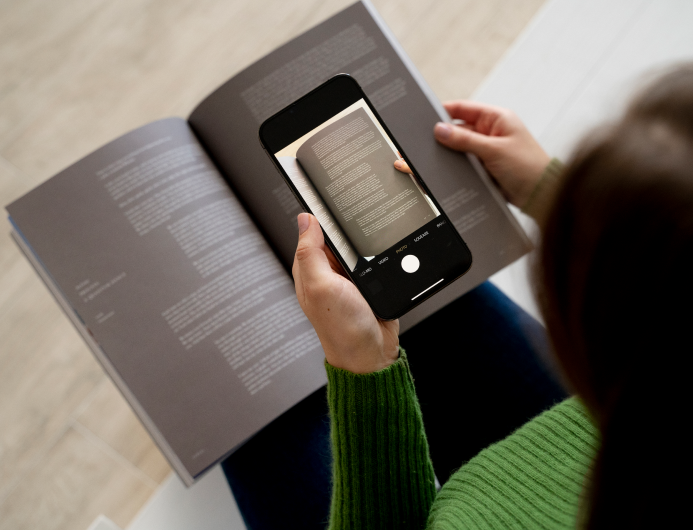

Comparing open-source React Native Document Scanners

In this post, we look at two popular open-source React Native document scanners. We compare their capabilities, customizability, ease of integration, and maintenance as well as their limitations.