Effective inventory management is the backbone of modern businesses. However, businesses often overlook the importance of tracking and managing all their inventory. Physical assets are treated as an afterthought, although keeping track of physical resources, such as tools or machinery, is crucial for optimal workflows.

Implementing an asset management system doesn’t have to be cumbersome and costly. The solution is simple, thanks to technology we already use and see on a daily basis: barcodes and ordinary smartphones.

In this article, you will learn more about using barcodes for asset tracking – and what technology you need to implement such a system.

What is barcode asset tracking?

Effective asset tracking requires a data carrier and a device to read and connect it to an asset management system. Inexpensive and easily affixed to physical assets, barcodes are a natural choice of data carrier.

Barcodes can encode numbers or short alphanumeric strings – well-suited for storing a unique asset identifier or asset number. This identifier can then be linked to a central asset management database.

Like this, barcodes become convenient keys to access an asset’s data in the database. This enables easy updates to the asset’s status whenever the barcode is scanned.

A scan might, for instance, set the status to:

- checked out, whenever the asset is being used

- checked in, whenever it has been returned

- in maintenance, whenever it is being repaired or updated

With the help of the asset ID, key details about the item, such as its condition, location, and maintenance history, can be tracked within the asset management system.

Barcodes vs. other asset tracking methods

Other technologies are used for asset tracking as well. Let’s explore how they compare to barcode systems.

RFID vs. barcode tracking

Radio frequency identification (RFID) uses short-range signals to automatically identify and track tags attached to objects. The technology doesn’t require direct line-of-sight, allowing for the simultaneous scanning of multiple items. However, this poses a risk to data security, as even outsiders with RFID scanners can potentially scan nearby tags. Besides, RFID tags are generally expensive due to the chips they contain – and require dedicated reader hardware.

Barcode labels are more affordable and more widely used than RFID tags, which makes the purchase of barcode scanner software more worthwhile.

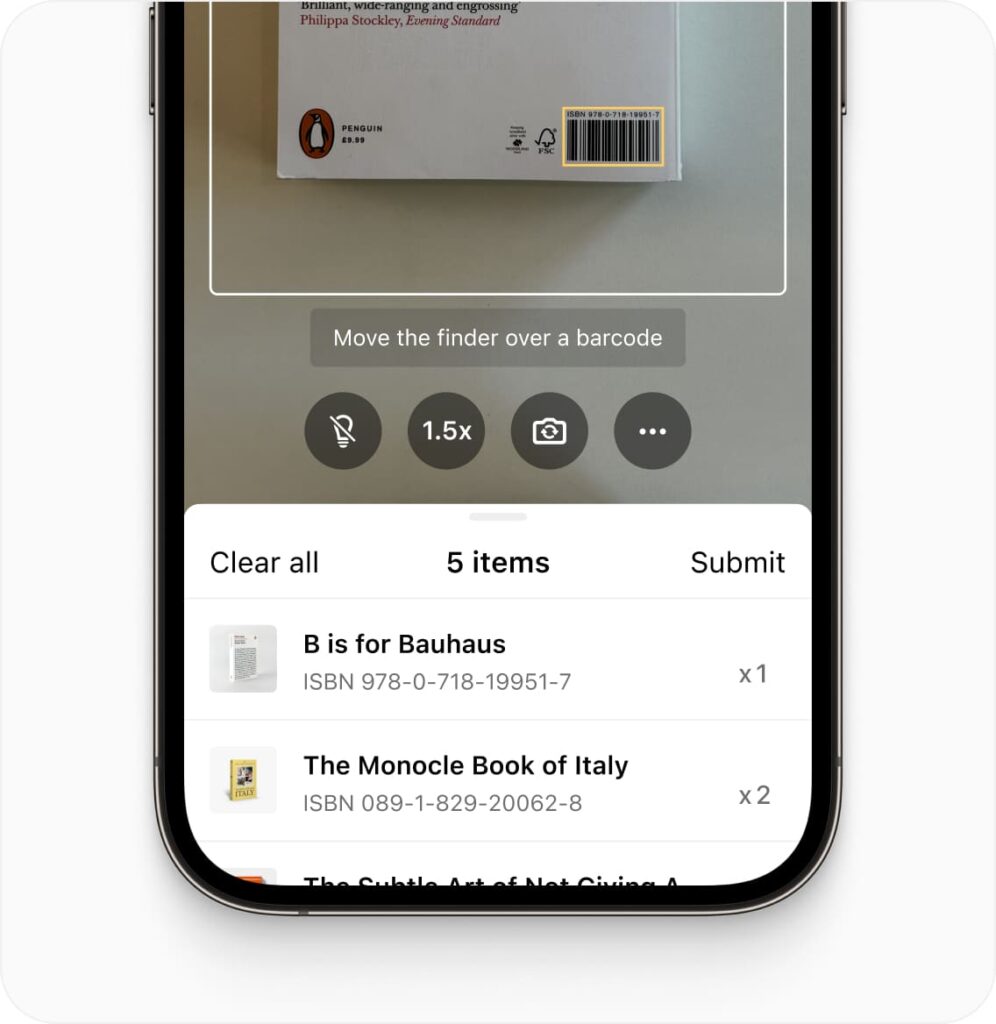

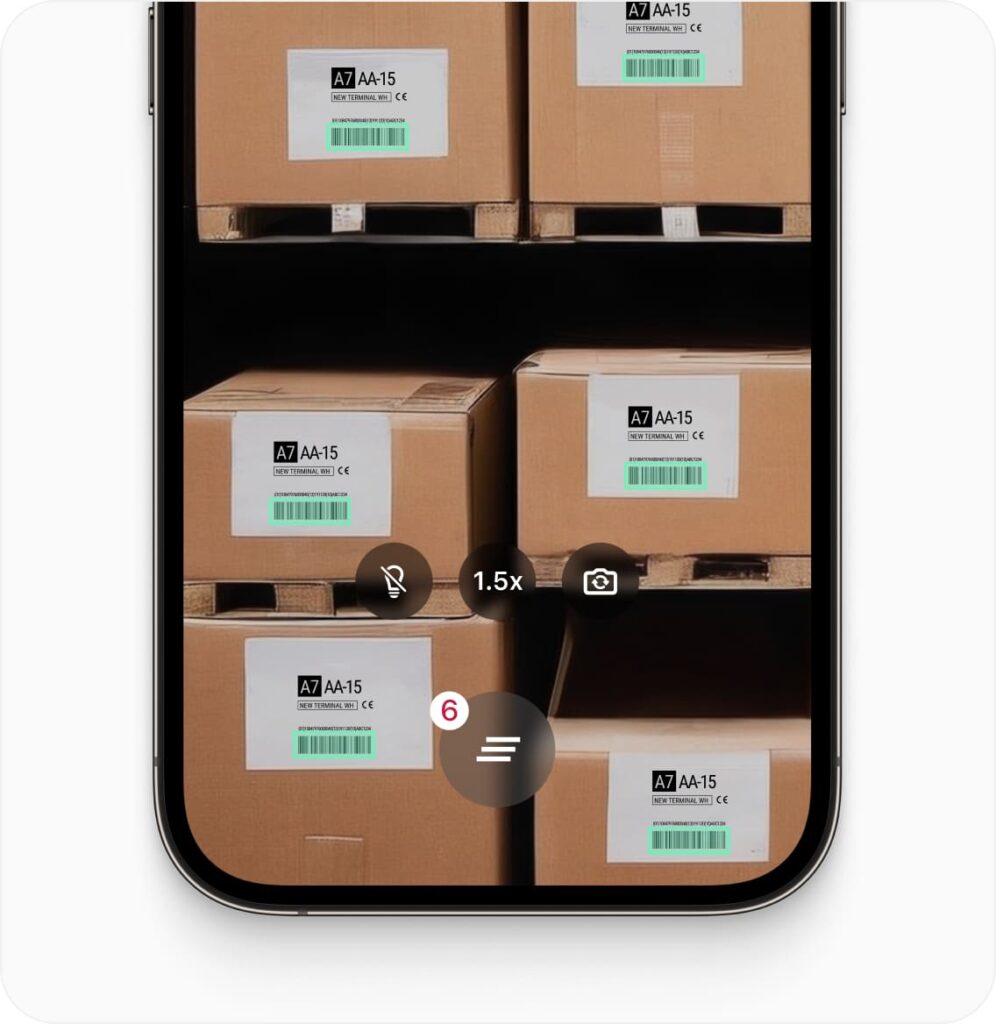

Modern barcode scanner software offers features such as multi-scanning, which enables scanning multiple barcodes in one go, as well. Even though RFID tags can store more data than barcodes, for asset tracking systems, the data capacity of 2D codes is sufficient.

NFC vs. barcode tracking

Near field communication (NFC) is a wireless communication technology commonly used in mobile payments. Unlike RFID tags, NFC tags can be scanned with smartphones, offering an accessible and secure method for exchanging data over short distances. However, NFC technology requires very close proximity for scanning and is more costly than implementing barcode tags.

GPS vs. barcode tracking

Since it can provide real-time location tracking via satellite communication, GPS technology is a popular choice for tracking assets in transit. However, it is costly and less effective for in-house tracking.

How to implement barcode asset tracking

In comparison to these other solutions, barcode asset tracking doesn’t require much: a barcode scanner and an asset tag generator already take you a long way.

Here are some key considerations for implementing a barcode asset tracking system.

1. Generating barcodes for asset tags or labels: Best practices

For internal purposes, such as barcode asset tracking, you don’t need to implement official barcode standards – you can simply develop an asset tracking system yourself.

You can use free barcode generators and a standard label or tag printer to encode a unique identifier into a barcode. This is often more cost-effective than purchasing pre-printed barcode asset tags.

Printing barcodes on-site can not only save costs, but also allows for flexibility. Once data has been assigned to a unique barcode, it can be printed and affixed to the corresponding physical asset immediately.

Serial numbers vs. unique identifiers

In an effective tracking system, every asset needs a clear identifier, such as a unique sequence of numbers. Some might want to reuse the serial number assigned by the item’s manufacturer. However, serial numbers are not guaranteed to be unique, and duplicate serial numbers will cause errors in tracking systems. Generating randomized, unique identifiers in barcodes yourself eliminates duplication risks.

Barcodes vs. QR Codes

1D barcodes can only store limited amounts of numeric or alphanumeric data in their bar patterns. QR Codes and other 2D codes, meanwhile, consist of pixel blocks that store data vertically and horizontally. This allows for higher data capacity in compact form. If you want to implement a system that gives immediate access to more asset information than just the identifier number, QR Codes are a better choice.

Additionally, QR Codes provide error correction, meaning they can be scanned even when dirty or damaged.

2. Choosing the right hardware: A comparison

Once you have decided on how to design your barcode asset tag, you will need hardware to scan it. Over the years, different types of barcode scanners have evolved. Here is a quick overview of the most popular choices:

- Charge-Coupled Devices (CCDs): CCDs utilize LED light to capture barcodes in their entire width. Even though their scanning capabilities are limited to 1D barcodes at short distances, they are usually accurate and offer high scanning speed. CCD barcode scanners are often robust and easy to use, but typically provide no direct visual feedback.

- Laser scanners: These scanners utilize rapidly moving laser beams, resulting in accurate scanning even in poor lighting conditions. Easy to use, they usually deliver high barcode detection capabilities. However, like their predecessor, they only scan 1D barcodes. As they contain moving parts, they may require more maintenance effort.

- Imager scanners: Imager scanners utilize cameras to take pictures of barcodes. This not only makes them capable of omnidirectional scanning, they can also scan both 1D and 2D barcodes – such as QR Codes – even when they are damaged. However, due to their advanced technology, they come with higher costs.

- Smartphones: Today, even ordinary smartphones can become reliable barcode scanners for your business. Enhanced with modern barcode scanner software, smart devices scan both 1D and 2D barcodes, even when damaged or poorly lit, and offer direct visual feedback. In challenging conditions, ruggedized devices still perform well. Thanks to their familiar feel, mobile barcode scanners are easy to use and require minimal training time. With strategies such as BYOD, smartphone barcode scanner solutions grow with your business and deliver unparalleled flexibility.

3. Choosing the right software: Considerations

To choose the right backend and scanner software for your barcode asset tracking system, you first need to identify your specific industry needs and asset types. After all, tracking IT equipment poses different challenges than warehouse inventory tracking or fleet management.

The software should offer essential features: asset registration, location tracking, condition descriptions, maintenance history, and lifecycle information.

If you decide on smartphones as barcode scanners, you will need powerful barcode scanner software that seamlessly integrates into your asset tracking software. Solutions with a flat annual fee keep the cost predictable and can be used on as many devices as needed.

The benefits of using mobile barcode scanner software for asset tracking

All in all, barcode asset tracking systems offer multiple benefits to businesses – especially when combined with flexible scanner devices, such as smartphones.

In brief, here are their advantages over other solutions:

- Cost-effectiveness: The initial costs for barcode label generation are low, and mobile scanners, such as smartphones, eliminate the need for expensive dedicated scanner devices.

- Ease of use: Barcode systems are generally easy to use, and require minimal employee training – especially with smartphones as barcode scanners. Scans are as simple as taking a picture, with a device that most are already familiar with.

- Improved speed and data accuracy: Mobile barcode scanner software offers helpful features such as user guidance, enabling employees to take quick and accurate scans. Enhanced image processing allows for even faster and more reliable scans.

- Wide range of applications: Smartphones can be used for other purposes as well, such as communication and document scanning, thus replacing several dedicated devices with one.

- Real-time asset visibility: Mobile barcode scanners provide instant access to comprehensive asset information, such as location, by displaying it on the screen with AR overlays.

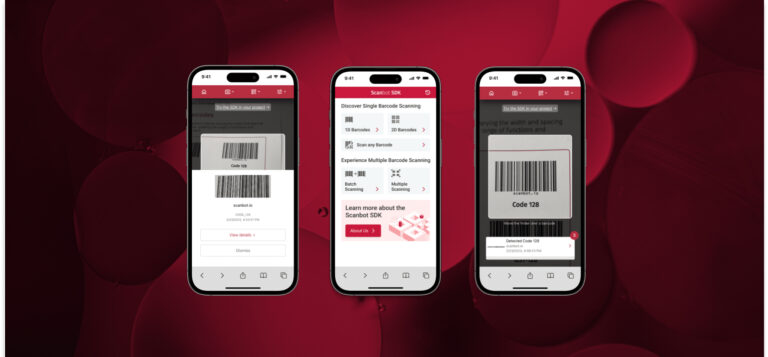

Keeping track of your assets with the Scanbot Barcode Scanner SDK

The Scanbot Barcode Scanner SDK offers several time-saving features that streamline asset management operations, such as Batch Scanning and Multi Scanning modes. It also comes with Augmented Reality (AR) Overlays to highlight barcodes or give additional information about scanned items directly on-screen.

Our Barcode Scanner SDK can be integrated into any mobile or web app for seamless communication with your asset management system, to be used on as many devices as you need. Our flat-fee pricing allows your business to grow without additional costs.

Experience for yourself how the SDK performs in our free web and mobile demo apps. If you are ready to try out the SDK for your project, get a free 7-day trial license, or contact sdk@scanbot.io.