Today’s supply chains are more complex than ever, with components and ingredients often passing through several partners and crossing numerous borders. While vast amounts of data are collected, it’s often disjointed – and losing track can have grievous consequences for both businesses and consumers.

Standards like the Food Safety Modernization Act (FSMA) aim to change this. They dictate comprehensive product traceability along the entire supply chain. Now, businesses have to respond – the FSMA Food Traceability Rule, in particular, demands compliance by July 2028.

In this article, we explore how an effective traceability system works, and how implementing barcode technology lays the foundation for such a system.

What is traceability?

Traceability is the ability to call up a product’s history throughout its journey along the entire supply chain, from sourcing the raw materials to the delivery and sale of the finished goods.

Product tracing and product tracking are sometimes used interchangeably. Though they are related, they carry different meanings.

What’s the difference between tracking and tracing?

Product tracking is a real-time process. As a product moves along the supply chain, data is collected from all concerned parties at every stage. By accessing the collected data, organizations can monitor the current status of an item, for instance its location.

Tracing typically happens after a product is finished, when it’s already in-store. Tracing back all production activities establishes a product’s history. This is vital information: In a product recall, for example, the producer may be able to narrow it down to certain batch numbers, rather than issuing a total recall.

Benefits of traceability systems

At their core, traceability systems are about collecting, storing, and sharing a variety of data – and doing so efficiently and accurately. The benefits extend well beyond compliance.

Comprehensive tracking of who handled a product, when, where, and how gives manufacturers a whole range of advantages:

- Supply chain insights: Monitoring supply chain operations in real-time helps identify bottlenecks and so optimize supply chain efficiency.

- Improved product safety: Traceability is crucial for maintaining product quality. It enables a quick identification of quality issues, which is vital in the food and healthcare sector. Fast, fine-grained identification of bad batches not only eliminates health risks, but also minimizes waste.

- Counterfeit protection: Traceability systems depend on unique identifiers, frequently with a barcode as the data carrier. Scanning this ID lets both consumers and businesses verify a product’s authenticity by tracing it back to the production facility.

- Regulatory compliance: Proving adherence to safety standards is crucial for businesses, especially in the food and healthcare sector.

- Inventory and operational planning: Traceability systems also facilitate inventory barcode management by providing real-time data on a product’s status and location. This prevents stock-outs – and lets operators identify batches nearing expiration.

- Consumer trust: Today’s consumers want to know where their products come from. Unique identifiers and mobile barcode scanning give consumers easy access to all the information they seek.

How businesses benefit from using barcodes in traceability systems

Implementing a barcode traceability system is fairly straightforward, as barcodes can be generated and printed on-site without special equipment. They are not only highly accessible, but also versatile, as they can encode a variety of numeric and alphanumeric information.

Let us explore some of the advantages of a barcode-based traceability system in more detail.

Lower costs

Barcode generators are easy to find, and smartphones can be enhanced with modern barcode scanner software to become reliable barcode scanners. This, along with methods like BYOD, makes using barcodes more affordable than NFC and RFID tags.

Existing infrastructure for real-time information

Commonplace barcodes like the Universal Product Code (UPC) and European Article Number (EAN) already encode product identifiers that facilitate tracking – in the form of the Global Trade Item Number (GTIN).

2D barcode symbologies can contain even more information, especially when they connect to online information through standards like GS1 Digital Link. They can provide data such as the GTIN, product IDs, manufacturer details, expiration dates, or nutritional information.

Speed and efficiency

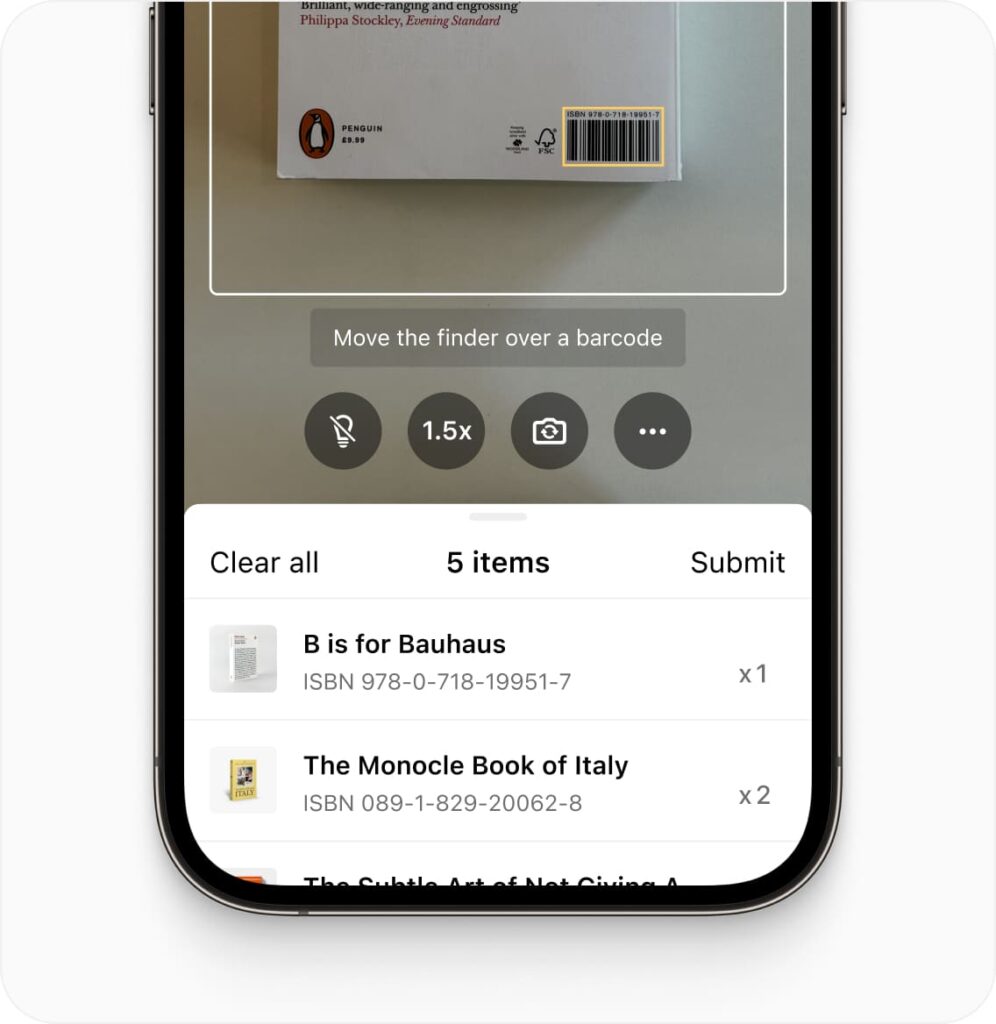

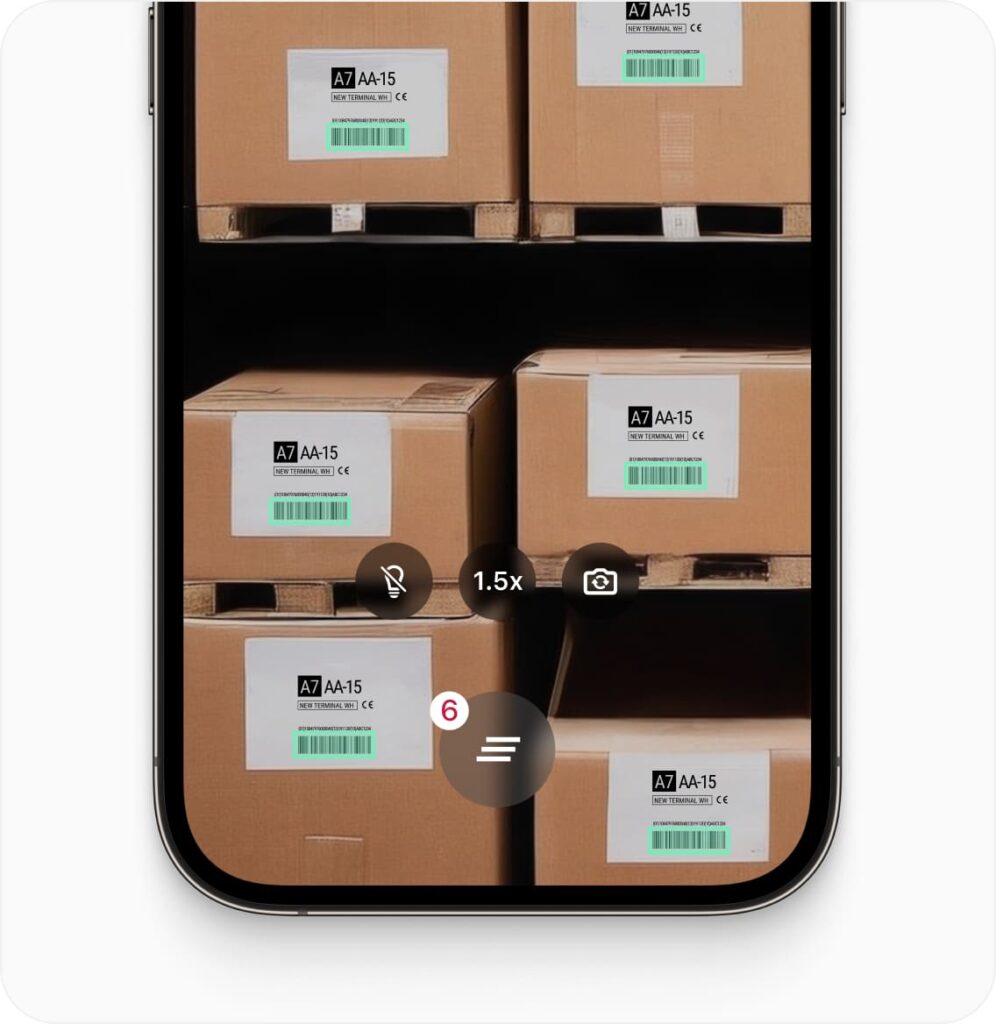

Mobile barcode scanners, in particular, often have unique features that enhance workflow speed and efficiency. Batch scanning enables scanning several barcodes consecutively, and multi barcode scanning enables capturing multiple barcodes in one scan.

Laser barcode scanners – but also NFC or RFID tag readers – rarely offer the same functionality, or only at a substantially higher cost.

Multi-purpose devices

Mobile devices eliminate the need for several dedicated devices and combine their functions into one. In addition to barcode scanning, mobile barcode scanners can be used for communication, inventory management, and more.

Example implementation of a barcode traceability system

Let’s see for ourselves how barcode traceability systems work. For this, we’ll follow a humble pot of yogurt on its journey through the supply chain.

- Dairy farm: Each cow wears a tag with a unique barcode. Farm workers scan it during milking to record production data and link it to a specific animal.

- Milk collection: Tanker trucks collect and transport the milk to a dairy factory. Their drivers scan barcodes at pickup and delivery, linking the load to tracking data like temperature readings that prove cold chain integrity.

- Production facility: The milk is pasteurized, cultured, and mixed with other ingredients. All ingredients are themselves scanned, which ties batch numbers to specific products for quality control.

- Packaging: The finished yogurt is packaged in plastic containers. Each pot receives a unique QR code, encoding production details, ingredients, and farm origin, before being packaged and palletized.

- Distribution: Pallets are stored, shipped, and received. The pallets’ own barcodes are scanned for inventory management and to record storage conditions.

- Retail store: The yogurts are placed on refrigerated shelves. Store employees scan their barcodes for inventory management.

- Consumer purchase: After checking the product’s journey with a simple barcode scan, a customer buys the yogurt.

Even this simple example shows how a product undergoes a multitude of steps before it is ready for sale or use. Thanks to barcode traceability systems, it is possible to track it at all times and retrace these steps – all the way to the source.

Conclusion

A series of quick scans at every point in the supply chain significantly enhances product traceability. Ubiquitous, inexpensive, and user-friendly, smartphones and tablets are the perfect tool to facilitate and speed up barcode scanning.

All that’s needed to turn a smart device into a reliable barcode scanner is an appropriate barcode scanning solution. Software development kits (SDKs) are ready-made sets of tools and resources containing everything you need to build your own barcode scanner app.

The Scanbot Barcode Scanner SDK reliably scans all common 1D and 2D barcodes, even when damaged or in low lighting. Thanks to its ready-to-use UI components, you can easily and quickly build an intuitive user interface. Features such as Batch Scanning or Multi Scanning speed up a range of workflows.

The SDK is available for Android, iOS, Web, Windows, and Linux and supports several cross-platform frameworks, including React Native, Flutter, and .NET MAUI. You can integrate it into your mobile or web app in less than an hour.

Experience the Scanbot Barcode Scanner SDK for yourself by trying the free Barcode Scanner demo app or running our example apps for various platforms.

Or why not test the SDK directly in your app? Start integration immediately with a free 7-day trial license.