Introduction

In an era where counterfeit products are beginning to flood the market, it’s becoming increasingly important to ensure the authenticity of products. The OECD estimates, that as of 2019, counterfeit products accounted for 3.3% of global trade, and a whopping 6.8% of EU imports. The situation has been further exacerbated by the recent raw material shortages, which have led to a scarcity of industrial parts. Consequently, industrial customers, often unknowingly, end up using substandard imitations of parts from established manufacturers.

The Threat of Counterfeit Industrial Products

These imitations can have an existential impact on the manufacturers of original parts:

Hence, these counterfeit products not only hurt the manufacturers of the original parts but also pose a significant risk to the end-users who rely on these parts for their operations. This is where the role of the barcode comes into play. Barcodes can serve as a reliable tool to check product authenticity, ensuring that customers get their money’s worth and manufacturers’ rights are protected.

Unmasking Counterfeits: The Role of Barcodes & Barcode Scanners

Mobile barcode scanners, like the Scanbot Barcode Scanner SDK, have emerged as a game-changer in this regard, enabling customers to check the authenticity of industrial parts within seconds! Each product comes with a unique barcode, displayed on the packaging and the product itself. This is a key tool in the fight against counterfeits, particularly fake barcodes.

The Process of Verification

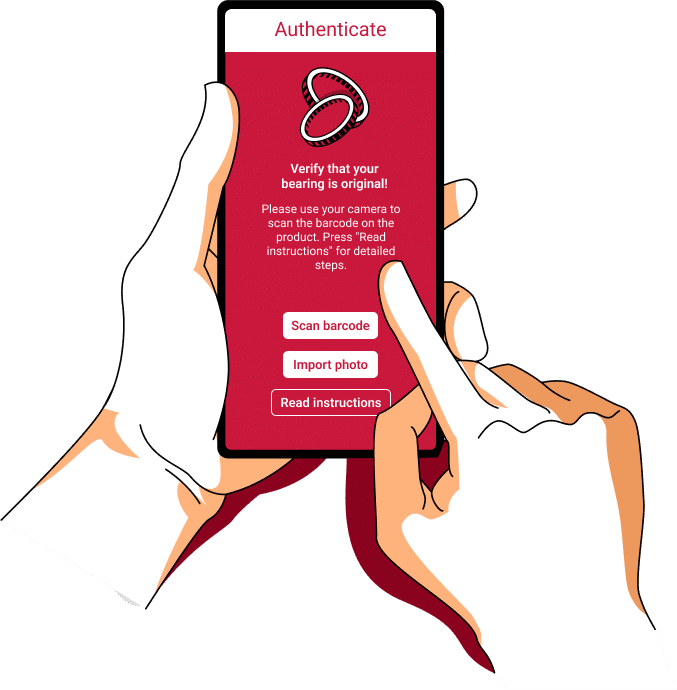

When a new shipment arrives, customers and all distribution partners along the supply chain can use the manufacturer’s proprietary authentication app to verify the authenticity of these products swiftly and seamlessly. Let’s walk through the process using the example of a ball bearing manufacturer:

- Customers scan the delivered bearings using the manufacturer’s authentication app.

- The scan triggers an authenticity check in the backend system.

- This system verifies whether a barcode has been registered and how often it has been scanned.

The Power of an Authentication App

Self-Authentication

Where buyers previously needed experts, they can now use the app to check whether a product is genuine.

Quick Verification

Customers receive immediate feedback on the authenticity of the products, ensuring they are installing genuine parts. This reduces the risk of installing counterfeit parts, which can have serious repercussions on industrial machinery.

Risk Prevention

The system detects and removes any counterfeits from the supply chain at an early stage. This prevents further circulation of fake products, thereby protecting both the manufacturers and the end users.

The scan triggers an authenticity check in the backend system, which verifies whether a barcode has been registered and how often it has been scanned to detect if registered barcodes have been simply copied.

A Lifeline Against Product Piracy

This simple yet effective method of verification can make it extremely difficult for counterfeiters to disseminate fake products. The immediate detection and removal of fake products from the supply chain help in mitigating the risk of counterfeits.

The Legal Angle

Moreover, the more product imitations are reported, the more information can be gathered. This valuable data can serve as a strong basis for legal prosecution against counterfeiters, further dissuading them from producing and distributing fake products.

Why use the Scanbot Barcode Scanner SDK?

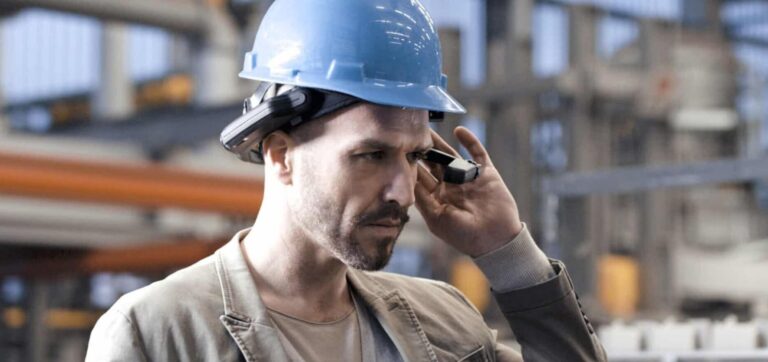

The fast, user friendly, and reliable solution for mobile barcode scanning in manufacturing. Enable your customers to scan barcodes quickly and easily even under the most difficult conditions:

FAQ

How does the use of counterfeit bearings impact machinery performance and safety?

Incorporating counterfeit bearings into machinery can lead to premature failures, increased friction, and unexpected downtimes. These substandard components may not meet the required specifications, resulting in safety hazards, costly repairs, and potential legal liabilities for businesses.

What other solutions can supply chain partners implement against counterfeiting besides authentification apps?

Source Verification: Procure products directly from authorized distributors or the manufacturers themselves.

Regular Audits: Conduct thorough inspections and audits of inventory to identify and remove counterfeit items.

Employee Training: Educate staff on identifying counterfeit products and the importance of maintaining supply chain integrity.

What are the common signs that a bearing might be counterfeit?

Counterfeit bearings often exhibit subtle discrepancies compared to genuine products. These can include differences in packaging quality, misspellings or inconsistencies in branding, irregularities in the bearing’s finish, and deviations in weight or dimensions. Utilizing authentication tools, such as barcode scanning apps provided by manufacturers, can help verify a product’s authenticity.