Retail warehousing faces unique operational challenges, ranging from manual inventory management to inefficient barcode scanning in environments with poor lighting. Traditional methods are time-consuming and often inaccurate, contributing to workflow bottlenecks and delays in supply chain processes. Software-enhanced barcode scanner devices address these issues through innovative features designed to streamline warehouse operations, ensuring fast, precise, and reliable scanning in various conditions.

Challenges in retail warehousing

Warehousing in the retail sector requires precise inventory management as goods move in and out. Employees are often responsible for manually counting items and using barcode scanners to track inventory levels. These tasks present several common challenges:

- Manual inventory management: Many warehouses still rely on manual processes, which are prone to human error and slow down overall operations. Counting items as they enter or exit the warehouse can be time-intensive, especially in large facilities with thousands of items.

- Ineffective barcode scanning in low-light conditions: Warehouses often have dark areas with poor lighting. Many barcode scanning solutions underperform in these conditions, resulting in inaccurate scans.

- Time-consuming scanning processes: In high-volume environments, manually scanning each item individually increases the time required to process shipments or manage stock, causing delays in downstream operations like order fulfillment and restocking.

These challenges require an advanced solution that enhances accuracy and increases operational speed. This is where barcode reader software like the Scanbot Barcode Scanner SDK comes into play.

Key features of the Scanbot Barcode Scanner SDK for retail warehousing

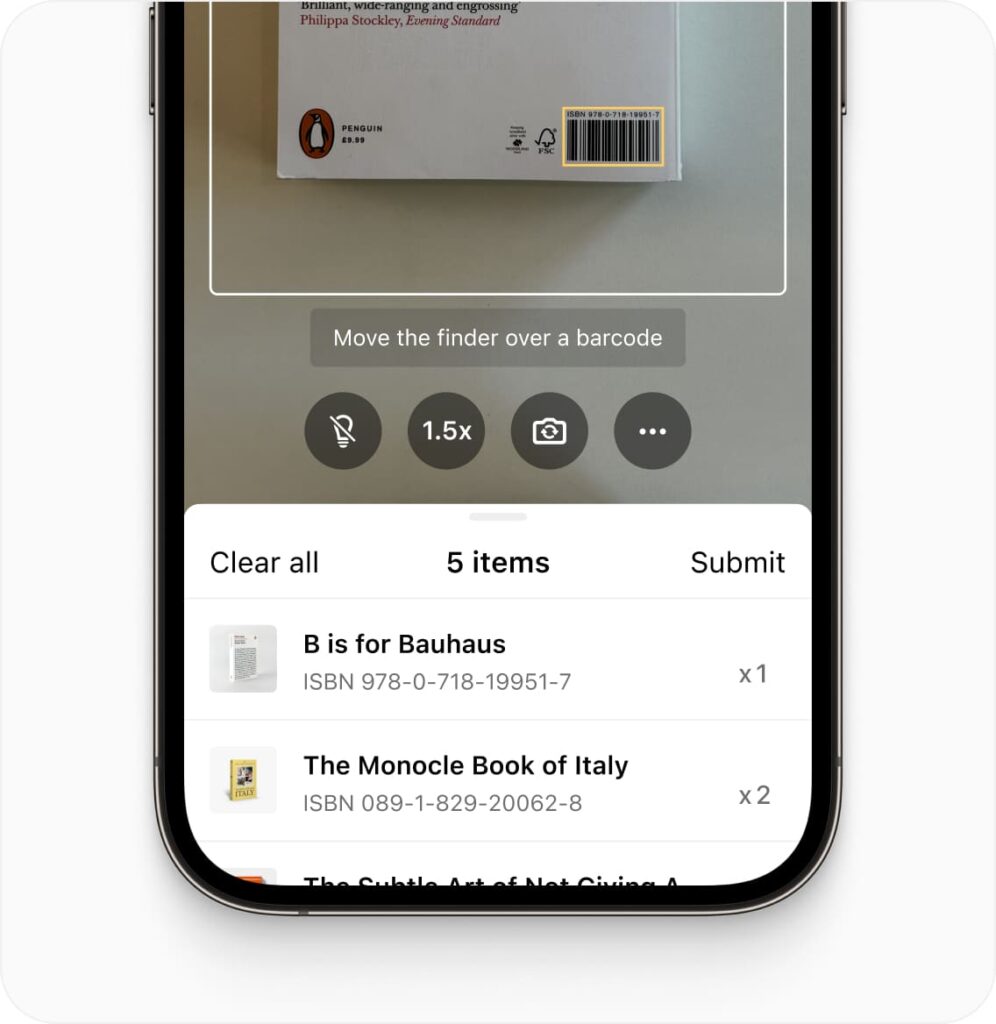

Single Scanning for precise inventory control

The Single Scanning feature enables employees to scan one barcode per session, ensuring accurate stock tracking. It’s particularly useful for reorders or shelf-level stock checks, allowing real-time updates to the inventory barcode system.

Example: Staff can scan shelf barcodes to trigger reorders, minimizing manual data entry and stock discrepancies.

Batch Scanning for faster operations

Batch Scanning allows users to scan multiple barcodes consecutively without pausing. Ideal for high-volume environments, it accelerates shipment processing and inventory intake.

Example: When receiving large shipments, staff can quickly scan items in bulk, speeding up intake and restocking.

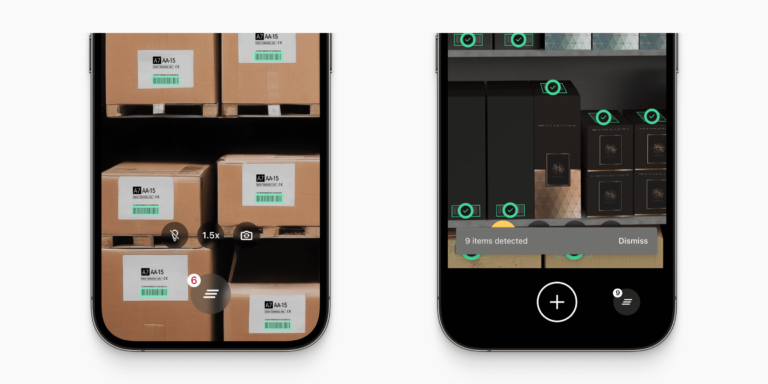

Multi Scanning for bulk orders

The Multi Barcode Scanning function captures multiple barcodes at once by hovering over them. This is efficient for scanning forms or packing slips with multiple items listed.

Example: Managers can scan documents containing several barcodes simultaneously, reducing the time spent processing incoming or outgoing deliveries.

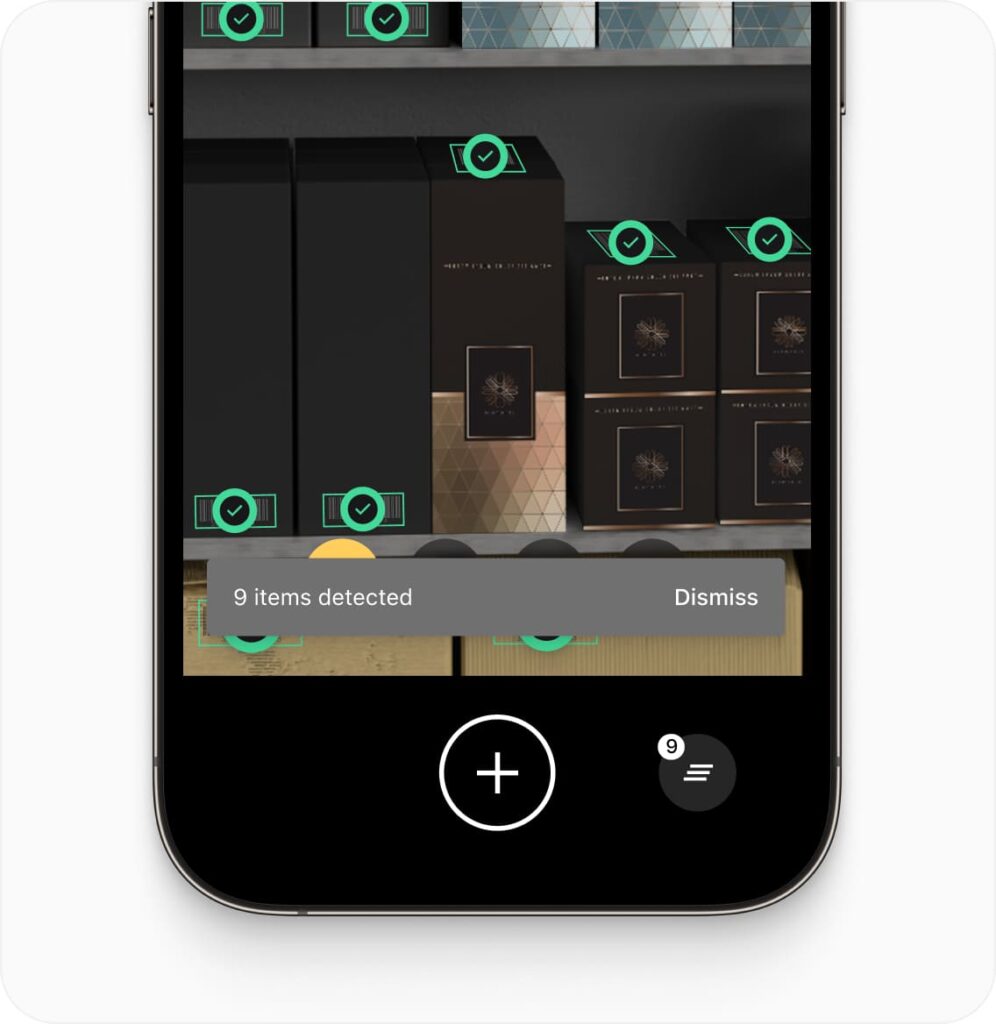

AR Overlay for visual feedback

AR Overlay visually frames recognized barcodes, providing instant feedback to ensure correct barcode capture. This reduces errors when scanning multiple items.

Example: AR Overlay helps employees confirm successful scans and prevent missed items.

Scan & Count for quick stock audits

The Scan & Count feature automates the counting of barcoded items in seconds, providing fast and accurate stock management.

Example: During the unloading of merchandise, employees can scan large volumes of items, ensuring real-time updates on how many goods have been added and reducing manual counting efforts.

Find & Pick for improved order fulfillment

The Find & Pick feature streamlines order fulfillment processes by guiding warehouse staff to specific items. Given one or more barcode values, it highlights the exact location of products in the warehouse, reducing search times.

Example: When fulfilling customer orders, warehouse staff can use Find & Pick to locate where the product is stored, minimizing time spent searching for items.

Enhanced configurations for warehouse environments

Retail warehousing often operates in challenging physical environments, such as areas with poor lighting or difficult-to-reach shelves. The Scanbot Barcode Scanner SDK offers configuration options that are tailored to these conditions:

- Flashlight configuration: Poor lighting and dark rooms can make barcode scanning difficult. The Scanbot SDK’s flashlight configuration allows employees to illuminate dark areas, ensuring consistent scan accuracy even in low-light conditions.

- Zoom and focus lock: For distant or hard-to-reach barcodes, the zoom and focus lock configurations enable scanning from afar without compromising precision. This reduces the need for employees to move heavy items or climb ladders to scan items located at high or difficult-to-reach locations. This improves safety, reduces manual effort, and accelerates scanning workflows in large-scale operations.

Optimizing retail warehouse operations with the Scanbot Barcode Scanner SDK

Through advanced features such as Single Scanning, Batch Scanning, Multi Scanning, AR Overlay, Scan & Count, and Find & Pick, the Scanbot Barcode Scanner SDK provides accuracy and efficiency in inventory management. Its enhanced configuration options, including flashlight support and zoom and focus lock, make it highly adaptable to warehouse environments, ensuring reliable performance even in suboptimal conditions.

By implementing the Scanbot Barcode Scanner SDK, retail warehouses can significantly improve operational speed, reduce manual errors, and ensure real-time inventory tracking. These advantages lead to more efficient workflows and, ultimately, a more streamlined supply chain. For more information on how the Scanbot SDK transforms real-life warehouse operations, find out how Cypher Robotics automated its inventory cycle counting system using the Scanbot Barcode Scanner SDK here.