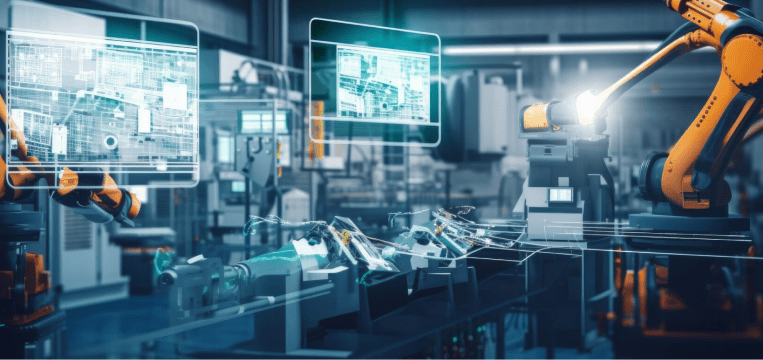

Machine learning (ML) technology allows a computer system to learn from data and improve its capabilities without explicit programming. Under the hood, machine learning involves advanced algorithms and complex statistical models.

One use case of the technology is in industrial robots, enabling them to evaluate enormous amounts of data, recognize patterns, and draw intelligent conclusions. For example, they can spot sources of error, increase employee safety, and speed up work steps.

Today, manufacturing companies increasingly use similar machine learning techniques to improve their operations across the board.

Let’s now take a look at 5 practical machine learning applications in manufacturing.

1. Predictive maintenance

A main application of machine learning in the manufacturing sector is predictive maintenance.

The issue: Unanticipated downtime and equipment failures substantially affect overall production speed and thus profitability. To minimize losses, manufacturers can use machine learning algorithms to examine historical performance data, detect patterns, and predict potential failures or maintenance needs. By proactively addressing issues before they occur, manufacturers can reduce downtime and streamline maintenance schedules to extend the lifespan of their equipment.

2. Smarter quality control

In traditional manufacturing, quality control relies heavily on manual inspections. Not only do these require a lot of time, they are also prone to human error.

Machine learning algorithms, conversely, can swiftly evaluate data collected from various sensors, cameras, and monitoring devices, detecting abnormalities, faulty components, or deviations from quality standards across the entire production process.

This real-time analysis allows producers to identify and remedy any problems at an early stage, preventing waste and ensuring consistent product quality.

3. Better supply chain management

With machine learning technologies, manufacturers can introduce cognitive supply chain management: By analyzing and automatically managing stock levels, shipping, and production, companies can keep entire supply networks running smoothly.

Furthermore, machine learning allows for effective cargo routing and planning, lowering transportation costs and enhancing overall logistics.

Finally, machine learning is also used for demand forecasting. Here, companies use these predictions to adjust their procurement, production, and distribution processes in advance, preventing both bottlenecks and excess capacity.

4. Process optimization & automation

A manufacturing process is complex, as efficiency and product quality depend on a plethora of variables. Fortunately, machine learning algorithms can analyze vast volumes of input data to detect potential for improvement.

Leveraging these insights, manufacturers can evaluate production processes, streamline workflows, and increase overall operational efficiency.

Likewise, machine learning is vital to automation, as it enables the seamless integration of robots and intelligent systems into production lines, thus improving speed, accuracy, and consistency.

5. Thorough risk management

Safety is paramount in manufacturing, and machine learning can play a vital role in risk minimization. By analyzing both historical and real-time sensor data, specialized algorithms identify potential safety issues, estimate accident probabilities, and recommend preventive measures.

With such a proactive strategy, manufacturing businesses promote workplace safety, reduce accidents, and protect their employees’ well-being.

Machine learning in manufacturing: conclusion

Machine learning gives companies in the industrial sector the means to reach new levels of productivity, innovation, and safety. By leveraging data analytics and automation, manufacturers can streamline processes, increase productivity, and boost their overall business performance.

Particularly in tandem with advances in IoT, machine learning and AI applications are progressively opening up new optimization and business opportunities across the manufacturing industry.