The shift to smartphone scanners

Traditionally, manufacturers relied on dedicated handheld barcode scanners for tasks like inventory management, asset tracking, and supply chain operations. Smartphone technology, however, is changing this. Modern smartphones can accurately scan barcodes, QR codes, and other machine-readable symbols, previously the domain of specialized hardware. This shift is driven by the need to optimize cost and operational efficiency, and leverages the ubiquity and versatility of mobile devices.

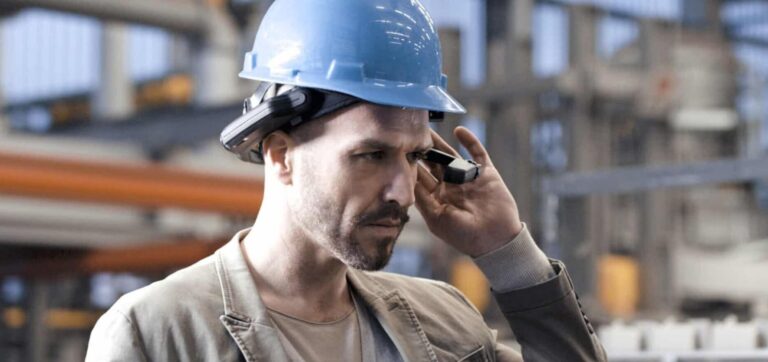

Mobile applications and software development kits (SDKs) for barcode scanning have made it very easy to integrate these capabilities into existing manufacturing processes. They also have more to offer than classic handhelds: With advanced features such as augmented reality (AR) overlays, real-time data processing, and seamless integration with ERP systems, they further enhance productivity.

Key drivers of adoption

- Cost savings: Smartphones are significantly cheaper than dedicated scanners.

- Ease of use: Employees are already familiar with smartphones, reducing training time and increasing productivity.

- Modern features: AR overlays, real-time data processing, and seamless ERP integration.

Lower acquisition cost

A major advantage of smartphone scanners is the reduced cost of acquisition. Companies can potentially eliminate it entirely by implementing a Bring Your Own Device (BYOD) policy, where employees use their own existing smartphones.

Even when new hardware is purchased, the cost savings are substantial. Dedicated industrial-grade scanners easily run to $800+ per unit, while mid-range smartphones can be acquired for $300 or less. Across a large workforce, these savings add up quickly. Additionally, the smartphone market is highly competitive, which keeps prices low.

Reduced maintenance cost

Smartphone scanners have significantly lower maintenance costs than traditional scanners. The number of smartphone vendors translates to increased competition, and the sheer number of devices to more affordable repair services. Unlike dedicated scanners, which often require costly shipping to specialized repair centers, smartphones can be repaired locally and affordably.

The modular nature of many smartphones allows for individual component replacements, further reducing maintenance costs. A battery or screen swap, for instance, is relatively simple. This is in stark contrast to dedicated scanners, which may well have to be replaced completely if a single component fails.

Scanning for all improves productivity

Smartphone scanners increase productivity by making scanning capabilities more accessible to employees. Because traditional scanners are costly, companies typically only buy a limited number for shared use. Employees then end up wasting time locating these devices when they need one. With smartphone scanners, each employee can have their own device, eliminating bottlenecks and enabling companies to streamline additional workflows.

The intuitive interfaces of smartphones allows employees to rapidly learn how to use the devices effectively as scanners. This familiarity boosts confidence and reduces training time, enhancing overall productivity.

Advanced features of smartphone scanners

Smartphone scanners offer a range of advanced features that enhance the user experience and productivity:

- Augmented reality overlays: Real-time visual guidance, step-by-step instructions, and virtual annotations improve accuracy and speed.

- Seamless software updates: Frequent updates ensure the latest features, security patches, and optimal performance.

- Familiar interfaces: Intuitive touchscreen interactions reduce the learning curve, speeding up adoption and increasing efficiency.

Potential challenges and solutions

While the advantages of smartphone scanners are compelling, some potential issues have to be addressed in manufacturing environments.

- Durability: Smartphones can be made to withstand harsh industrial conditions with rugged cases and other protective measures.

- Battery life: Charging stations, spare batteries, and other power management strategies ensure continuous operation even with power-hungry applications.

- Security: Robust encryption and access controls will safeguard against cyber threats, ensuring data integrity. Offline scanners provide better protection than cloud-based scanners.

- BYOD policies: Clear guidelines and protocols help employees to effectively separate personal and work-related data, maintaining privacy and security.

Long-term value

Smartphone scanners enable long-term operational improvements and cost reductions. By equipping more personnel with affordable scanning capabilities, manufacturers can streamline more processes, reduce bottlenecks, and so enhance efficiency. Familiar interfaces reduce the need for training, while advanced features increase productivity.

Cost savings from reduced capital expenditures and maintenance expenses can be reallocated to other areas, fostering innovation and growth. The flexibility and scalability of smartphone scanners allow manufacturers to adapt to evolving needs and future-proof their operations.

The future of scanning technology

The future of scanning technology in manufacturing is promising, with advancements in AI, AR, and IoT. AI-powered image recognition and object detection can streamline tasks like inventory management and quality control. Augmented and Mixed Reality technology are useful for real-time guidance, minimizing errors and enhancing productivity. The expansion of IoT and 5G networks is enabling more advanced scanning applications and even faster data exchange, unlocking further operational efficiencies.

By adopting smartphone-based solutions and other cutting-edge technologies, manufacturers can achieve new levels of efficiency, productivity, and cost savings, positioning themselves for long-term success in an increasingly connected and data-driven world.