Barcodes are essential for industries like retail, logistics, and manufacturing, which involve long-distance transport, multiple reloads, and highly variable environmental conditions. All this can affect barcode labels, making them hard to read with traditional scanning devices.

Let’s take a look at common problems you’re likely to encounter when working with barcodes – and at what you can do to overcome them.

💡 We’ve included various examples of damaged barcodes in this article. You’re welcome to use our free Barcode Scanning Demo App to try scanning them.

Common problems with barcodes

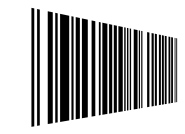

Ripped barcodes

Rough handling can lead to a part of a barcode label being ripped off. This doesn’t necessarily make it unreadable, however: The data in a 1D barcode (e.g., UPC, EAN, Code 93, or GS1 DataBar) is encoded in the width of the black bars and the white space in between, not in their height (with some exceptions). So, as long as the remainder of the label has all the bars in an unbroken line, you can still read it with a good barcode scanner.

However, if a barcode is ripped vertically, no barcode scanner will be able to recover the data. Therefore, it’s best to prepare for this scenario in advance, e.g., by attaching multiple copies of the same barcode. It may also be worth switching to a 2D barcode, since two-dimensional symbologies like QR and Data Matrix have a much higher error tolerance.

Worn, dirty, or scratched barcodes

Dirt, wear, or scratches on a barcode label are less of a problem for barcode scanning software, but might pose a problem to laser scanners. We trained our Barcode Scanner SDK using computer vision algorithms and machine learning models to check for discrepancies in the barcode’s line sequence and restore any damaged parts. In most cases, this enables it to read the encoded data without issues.

Poorly printed or blurry barcodes

Bad print quality greatly reduces a barcode label’s readability. Therefore, using a label printer specifically made for barcodes is crucial.

However, should you encounter poorly printed barcode labels, modern scanning technology can go a long way in helping you read them. Thanks to the machine learning model powering our SDK, printing artifacts and washed-out lines don’t stand in the way of accurate scanning results.

But what if you need to scan a barcode from a blurry photograph? Here, too, powerful barcode scanning software can compensate, allowing you to read the barcode’s data correctly.

Very small or distant barcodes

Sometimes the problem is not the barcode label’s quality – what if a barcode is just too small or too far away?

Our Barcode Scanner SDK has two special scanning modes to deal with these problems: One lets you zoom in on distant barcodes. The other uses a locked camera focus to help you scan very small barcode symbologies like Micro QR. The former is especially important for warehousing and other use cases where the labeled items are not easily accessible. Fixed-focus scanning, on the other hand, is useful when scanning tiny labels, such as those on lab sample tubes.

Curved barcodes and difficult angles

Another common issue involves barcodes that can only be scanned from an angle or that are printed onto curved surfaces. They are challenging to read for traditional laser scanners, since the light doesn’t bounce off them correctly.

Mobile barcode scanning software using computer vision, on the other hand, can detect which areas of a barcode are least distorted to accurately read the data.

Barcodes in poor lighting conditions

Barcode scanners rely on the contrast between the black lines and the white space in between, so poor lighting can severely affect a code’s readability. With smartphone-based scanners, you can use the built-in flashlight, although this can produce glare. That’s why your scanning software should be able to handle low-contrast barcodes as well.

When our Barcode Scanner SDK detects a poorly lit 1D barcode it cannot read, its machine learning model applies a binarization filter to enhance the contrast and tries to scan the barcode once more. For 2D barcodes, our algorithms can work around the poor lighting conditions even without binarization.

How you can read barcodes in all conditions

All the issues mentioned above are quite common when working with barcodes. Thankfully, modern scanning software handle them with ease.

Based on our many years of experience working with enterprises that use our barcode technology on a daily basis, we have outfitted our Barcode Scanner SDK with specialized modules for scanning barcodes in any condition.

The SDK’s computer vision capabilities have been optimized using machine-learning algorithms, ensuring accurate reads even from scratched, distorted, poorly printed, or blurry barcodes.

See for yourself by trying out our free Barcode Scanning Demo App – or contact our solution experts so we can discuss your individual use case. We also offer a free 7-day trial, so you can get started with the integration into your mobile or web app right away.

FAQ

How do environmental factors affect barcode readability?

Environmental conditions can significantly impact barcode readability by altering the barcode’s clarity, contrast, and integrity. Excessive moisture can cause barcode labels to smudge, peel, or fade. Water damage can also make printed barcodes illegible, especially if the ink is not waterproof. Industries like logistics and healthcare use laminated labels or synthetic materials to prevent degradation. Heat can cause barcode labels to warp, fade, or even melt, while cold temperatures can make labels brittle and prone to cracking. Chemicals in manufacturing or cleaning processes can erode barcode labels, while prolonged exposure to sunlight (UV radiation) can fade printed barcodes over time. To prevent this, industries use chemical-resistant coatings or laser-etched barcodes on durable surfaces. Scratches, dirt, and abrasions from handling, shipping, or storage can obscure barcode lines and reduce scanner accuracy. Protective coverings, direct part marking (DPM), and frequent label replacements help mitigate this issue.

What industries are most affected by barcode damage, and how do they handle it?

Retail & E-commerce: Barcode damage causes checkout delays and inventory mismatches. Retailers use durable thermal printing, protective coatings, and backup SKU tracking to prevent disruptions.

Logistics & Warehousing: Shipping labels face rough handling and weather exposure. Companies use high-durability labels, industrial printers, and AI-enhanced scanners to improve readability.

Healthcare & Pharmaceuticals: Damaged barcodes on patient wristbands or medications can lead to critical errors. Hospitals use laser-printed wristbands, laminated medication labels, and redundant barcoding for reliability.

Manufacturing & Industrial Production: Scratches, chemicals, and dust degrade barcodes. Manufacturers use direct part marking (DPM) and industrial scanners to ensure long-term readability.

What are the benefits of using 2D barcodes over 1D barcodes in challenging conditions?

2D barcodes, such as QR codes and Data Matrix codes, can store more information in a smaller space and include error correction capabilities. This means they can often be read accurately even if a portion of the code is damaged or obscured. In contrast, 1D barcodes have limited data capacity and lack robust error correction, making them more susceptible to unreadability when damaged.