As the number of products in a warehouse grows, finding the correct items to fulfill a customer’s order takes longer and longer. Companies can increase throughput by digitizing their workflows – which means saying goodbye to paper pick lists.

Good warehouse processes should involve as little reading and manual data entry as possible, since both waste valuable time and are prone to mistakes. Instead, picking instructions should be unambiguous and automatic to minimize room for error.

Pick-to-light solves this problem by using light signals to guide warehouse workers to the correct picking locations.

How pick-to-light works

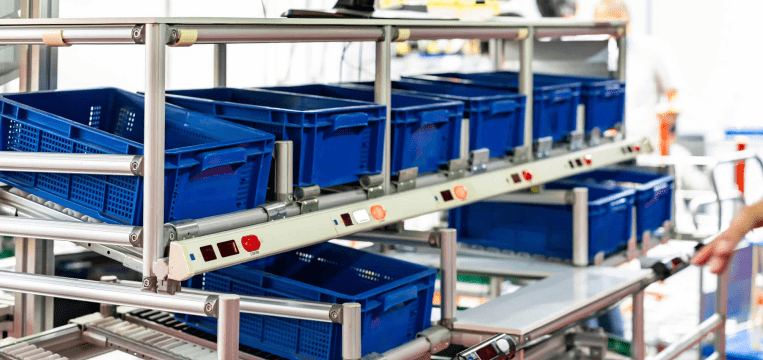

Pick-to-light (also called pick-by-light) is as simple as it is effective: Warehouse workers scan a barcode containing the order details, which are then transmitted to the picking system. A light indicates from which shelf or rack the workers should pick the first item.

At the picking location, a small display shows how many of the item they need to pick. Workers then only have to retrieve the indicated amount and confirm this with a quick button press.

They then proceed to the next light signal and repeat the process until the order is complete, also indicated by the system.

Finally, they bring the picked items to the sorting station for packing.

Pick-to-light is easy to understand, removes language barriers, and has built-in checks to correct human error. This makes it the perfect fit for warehouses that stock large numbers of different items.

Advantages of a pick-to-light system

Overall, a pick-to-light system offers the following benefits to warehouse operators:

Faster picking

Light-directed picking increases efficiency by reducing the time it takes to pick an order. Workers no longer need to search the shelves for items manually: They can see the next picking location at a glance.

Better accuracy

Working with a pick-to-light system reduces errors and so helps ensure accurate warehouse order fulfillment. The electronic display at the picking location clearly indicates which items to retrieve and how many, eliminating any ambiguity.

Less training needed

Training new warehouse workers can be time-consuming and expensive. Implementing light-directed picking reduces training time and cost by simplifying order picking. Not only does the system guide workers through the process, there is also no language barrier. This reduces picking errors significantly.

Real-time inventory tracking

Since it is constantly connected to a warehouse’s inventory management software, a pick-to-light system updates inventory levels as items are picked. This not only allows better item tracking, but also efficient restocking.

Customizable

Operators can tailor pick-to-light systems to the needs of a specific warehouse. The lights and the electronic displays can be set up in various configurations to match the layout of the warehouse. The system can also be programmed to handle different types of items, such as fragile items that require special handling.

Pick-to-light vs. put-to-light

While a pick-to-light system shows workers where to take items from, a put-to-light system shows them where to place the picked items. This allows workers to efficiently and accurately process several orders at once.

Put-to-light involves the following steps:

- Several items from different orders are collected at once (e.g., by using a picking cart).

- The items are transported to the sorting station.

- Scanning the items’ barcodes triggers the light signals for the corresponding containers.

- The items are sorted into the indicated containers for each individual order.

- The orders are packed and shipped out.

Put-to-light systems further increase throughput, especially in big warehouses.

Another important use case for put-to-light is returns processing. Here, workers simply scan the barcode on a return item, and the light signal instantly shows them where to put it. They then push a button to confirm the action, and the inventory count updates automatically.

Pick-by-scan

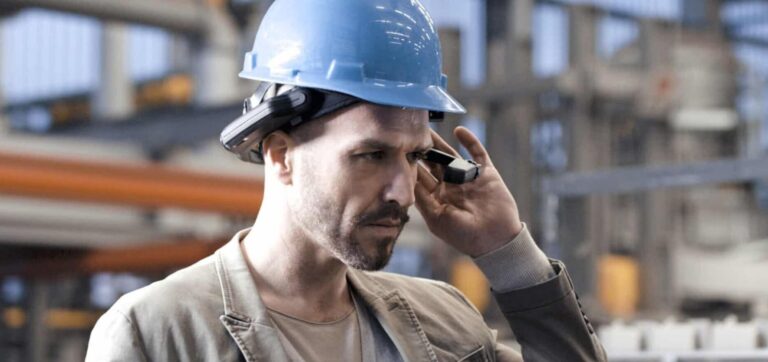

A popular variation of the pick-to-light process is pick-by-scan. For this method, workers use a mobile barcode scanner with a screen – often simply a smartphone with a picking app. The display shows them the storage location of an item and the number to be picked. They confirm completion by scanning the barcode on the item itself or one attached at the pick position.

The key advantage of pick-by-scan is that no dedicated displays or lights are necessary. Instead, the workers handle every step of the picking process with a single device. Scanning barcodes, finding the picking locations, and confirming pick completion can all be done using nothing but a smartphone and a picking app.

Using a smartphone-based barcode scanner for pick-to-light

A mobile barcode scanner is integral to every pick-to-light, put-to-light, and pick-by-scan system.

The pick list itself is initiated by scanning a barcode, which also activates the indicator lights. Workers then take out the specified quantities and confirm by scanning each item’s barcode once or pushing a button on the pick-to-light display. They move the item to the location indicated by the put-to-light system and also confirm this by scanning the barcodes or pressing the button.

The process is straightforward, but the time it takes to complete it depends in part on the quality of the barcode scanner. The capabilities of modern smartphones make them perfect for scanning large numbers of barcodes at once or in quick succession. Together with the right scanning software, these devices can speed up warehouse operations significantly.

Our Barcode Scanner SDK can be integrated into any mobile or web app within a week. It seamlessly communicates with backend solutions and supports all common barcode symbologies. The intuitive user interface ensures that even inexperienced workers can easily use the scanning functionalities.

Additional features like an AR overlay, a batch scanning mode, and special settings for very small or distant barcodes make our SDK an all-round solution for warehousing use cases.