In recent years, demand for 24/7 product availability and next-day delivery has skyrocketed. One consequence is that warehouse size is increasing. These days, 63% of U.S. warehouses are larger than 25,000 sq ft – a challenge for all warehouse workers and operations involved. Warehouse managers urgently need to find ways to speed up processes.

Warehouse pickers are critical to smooth warehouse operations. They are responsible for retrieving the correct items. To locate them, however, they are often only equipped with a paper pick list. It is a time-consuming, error-prone approach.

Digitizing warehouse processes such as picking is crucial for gaining a competitive edge while navigating this rapid growth. This article will introduce the pick-by-scan approach, and explore how it can benefit from mobile barcode scanning.

How pick-by-scan works

Pick-by-scan is a widespread method of order picking that streamlines operations for warehouse workers. Essentially, it replaces paper pick lists with a mobile data collection tool – a device with an integrated barcode scanner and a display. It guides warehouse workers through the picking process with barcode scanning.

Pick-by-scan involves mobile handheld computers, usually smartphones or tablets. These are equipped with enterprise barcode scanning functionalities and connected to a warehouse management system (WMS) or an enterprise resource planning system (ERP).

Let’s delve into how such a system works step by step.

- The system generates a picking list, which specifies the items to be picked and their location in the warehouse. It can include item descriptions, quantities, and other order details.

- A warehouse worker receives the list and checks the picking information displayed on their device.

- At each storage location, the warehouse worker scans the barcode of the location and the item to confirm the pick.

- Once all items have been picked, the system can automatically generate packing lists and shipping documents.

Pick-by-scan and pick-to-light – similarities and differences

Pick-by-scan is a variation of pick-to-light, an older method similarly meant to streamline the order picking process. Here, special light indicators guide workers to the picking locations.

Both systems guide workers to the correct picking location while simultaneously updating inventory levels in real time. This not only ensures fast picking, but also accurate inventory tracking and efficient restocking.

However, pick-by-scan and pick-to-light differ in hardware usage and operational methods. Pick-to-light relies on an entire system of fixed lights or displays. In contrast, pick-by-scan uses mobile barcode scanners, such as smartphones, to display the location and quantity of items, eliminating the need for extra hardware.

Consequently, pick-to-light is generally more expensive due to hardware and installation costs. Pick-by-scan leverages mobile devices, which often already exist and so don’t generate additional costs.

Benefits of a pick-by-scan system

Replacing pick lists with pick-by-scan is a major step towards a paperless process that saves resources – one from which warehouse operations benefit in several additional ways.

Faster picking

A pick-by-scan system can significantly speed up the picking process thanks to the automatic guidance it provides to warehouse workers. It also saves time by eliminating the need to print, distribute, process, and otherwise handle the printed picking lists.

Reduced error rates

As each item has to be scanned, and the barcode scanner provides direct feedback, pick-by-scan minimizes picking errors and ensures accurate inventory levels.

Cost savings

Pick-by-scan reduces costs associated with paper, printing, and manual data entry. Furthermore, strategies such as BYOD can keep hardware costs extremely low.

Real-time communication

Orders and inventory updates are instantly communicated, enabling subsequent stock reconciliation and real-time inventory updates. In turn, this reduces administrative overhead and costs.

Challenges of a pick-by-scan system

Successfully implementing a pick-by-scan system does involve overcoming certain challenges.

The first of these is that scanning conditions are not consistent in warehouses. Damaged barcodes and low light can complicate the scanning process, especially for older scanner systems. This can cause delays and potentially result in misreads.

Many pick-by-scan systems also build on dedicated barcode scanners, rather than modern mobile devices. Warehouses that go with such a system will have to invest in costly hardware. And warehouse pickers who have to operate those bulky scanning devices lose their freedom of movement for other tasks.

How to overcome these challenges with mobile scanner software

Mobile barcode scanner software addresses all these challenges, further streamlining pick-by-scan and boosting its advantages. The key is to leverage smart devices – they are the perfect platform for modern and efficient barcode scanners.

Smartphones are ubiquitous and easy to use. Modern devices are light and fit into every pocket, enabling hands-free operations. Using pre-existing smartphones minimizes additional costs and brings another advantage: Workers will already be used to operating them. This makes them a clear winner compared to bulky dedicated scanner devices.

Introducing the Scanbot Barcode Scanner SDK

Are you looking for barcode scanner software to enhance your pick-by-scan processes? The Scanbot Barcode Scanner SDK has got you covered.

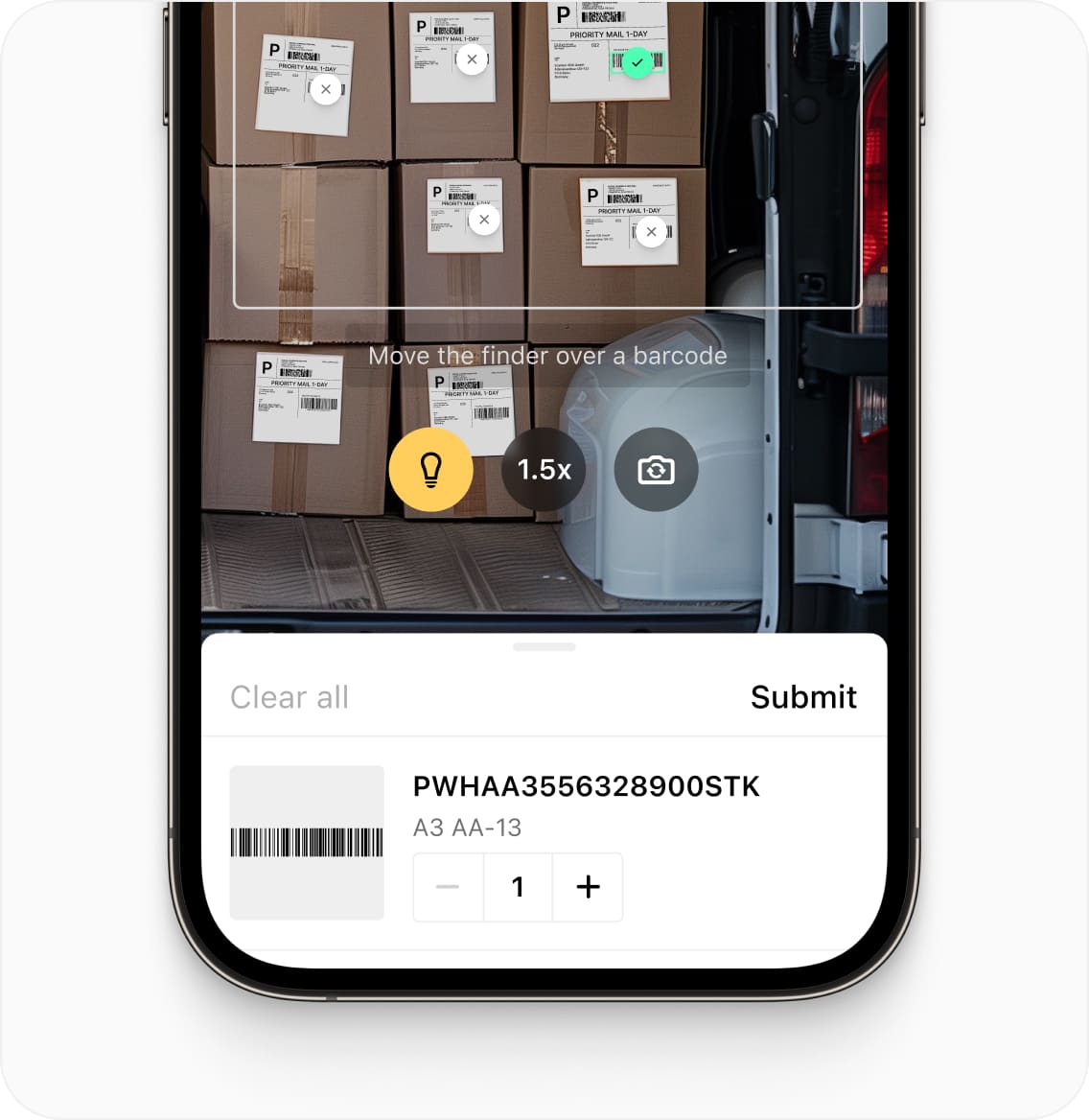

With a scanning speed of 0.04 seconds per barcode and the ability to reliably scan even tiny or damaged barcodes in low-light environments, the SDK is a perfect fit for the fast-paced, real-life environment of warehouses.

Our Barcode Scanner SDK can be integrated into any mobile or web app and enables seamless communication with your WMS and ERP. It supports all common barcode symbologies, including the standards used in warehouse operations.

The SDK operates entirely offline, with no usage tracking, providing complete data security. This also ensures top performance regardless of network connectivity, including in offline environments.

The Scanbot Barcode Scanner SDK comes with features tailor-made for enhancing pick-by-scan workflows:

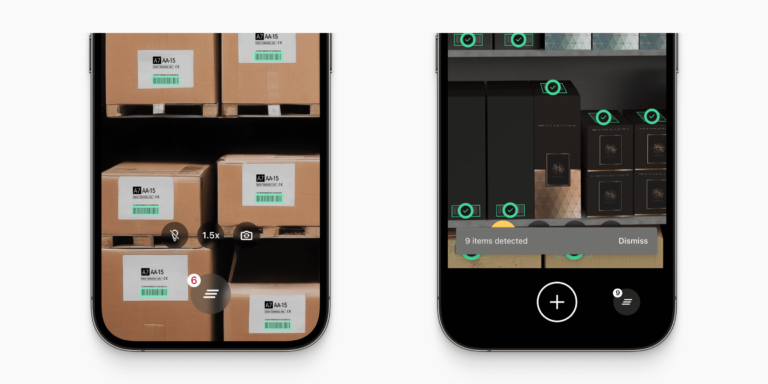

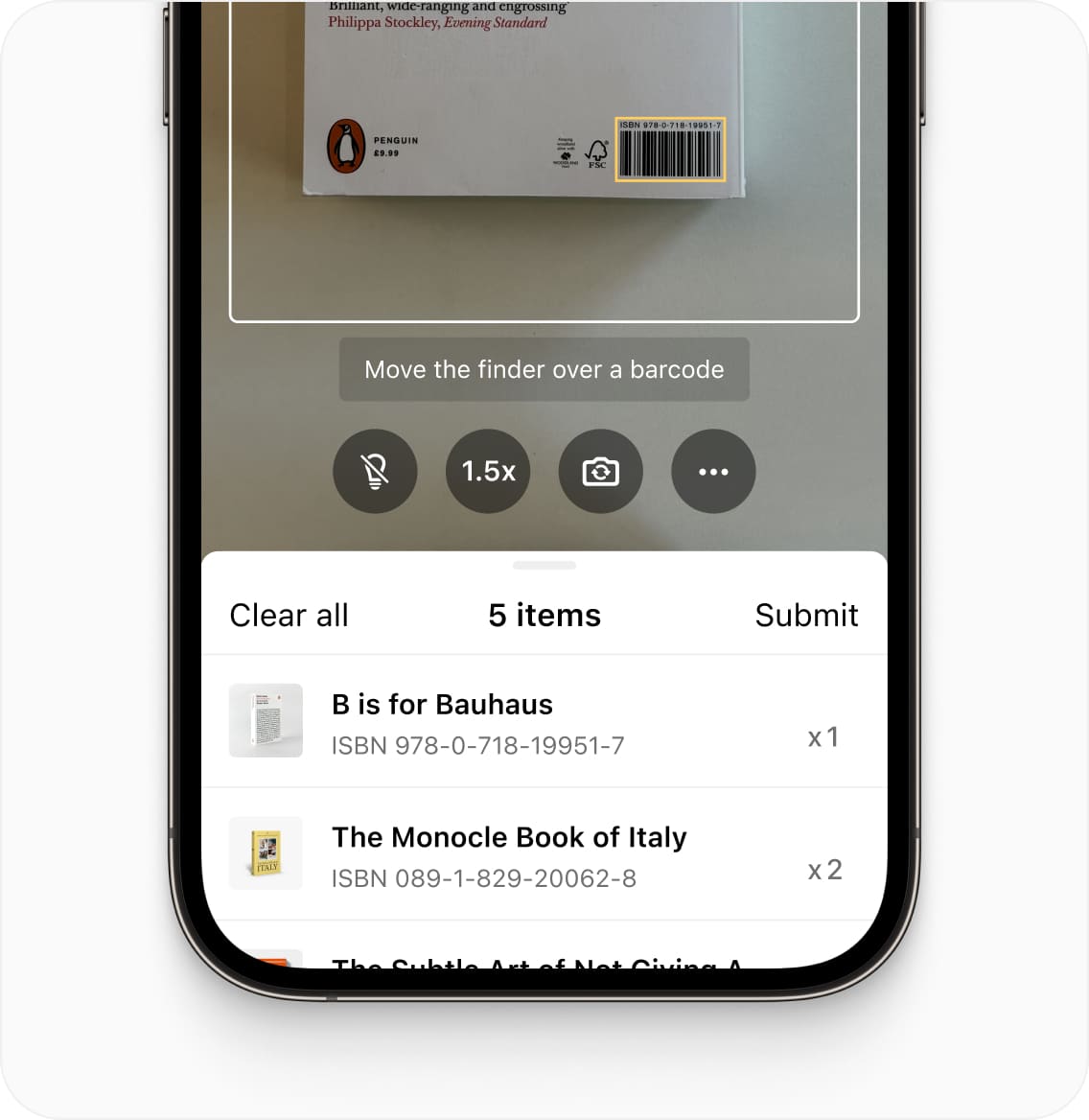

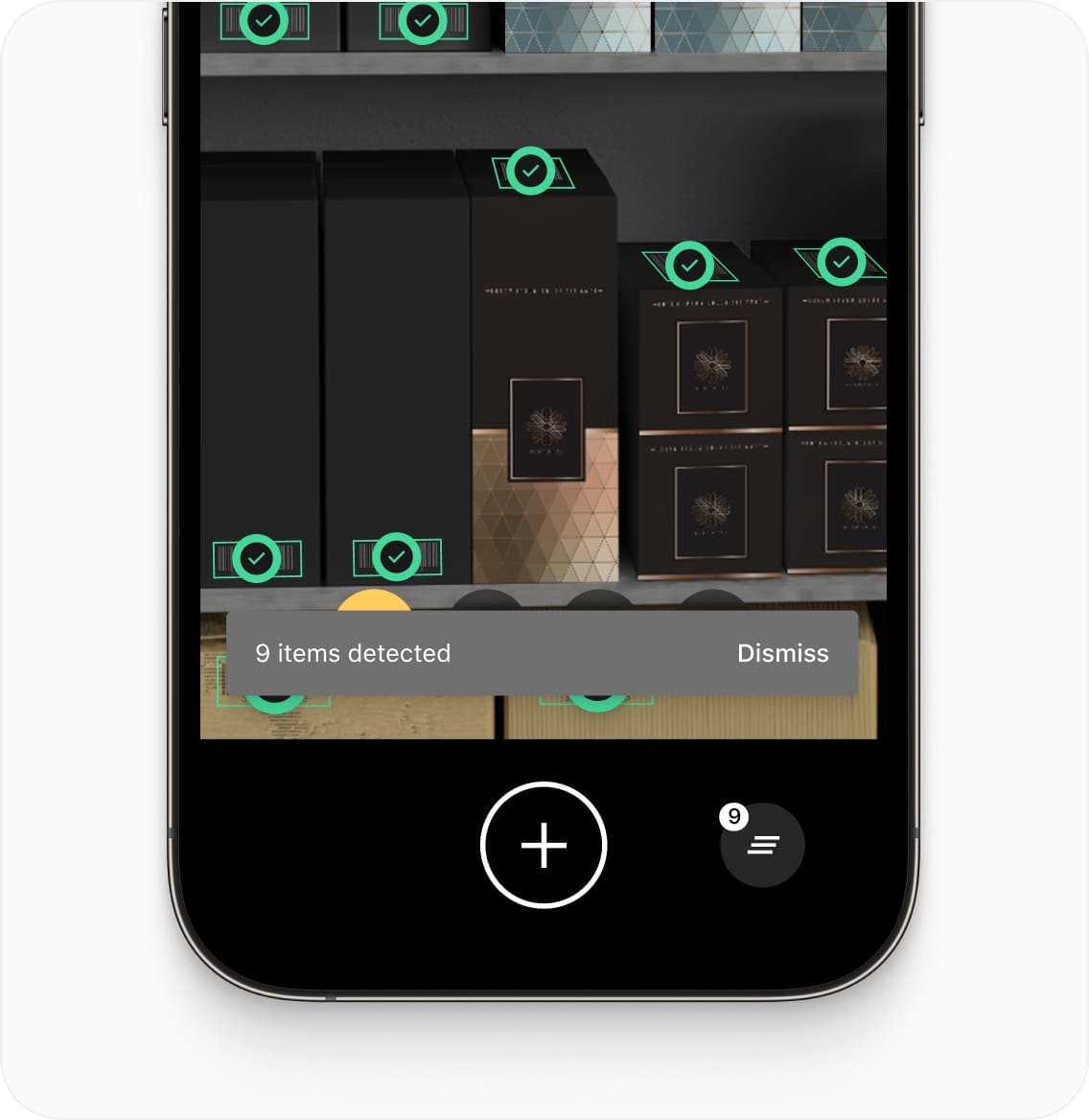

- Find & Pick: The SDK will visually highlight and scan correct items if their barcode values have been set first. It is specifically designed for pick-by-scan, where warehouse workers have to find items from their list.

- Batch Scanning: Enables scanning a series of barcodes without closing the scanning screen, which is ideal for picking several products for one order.

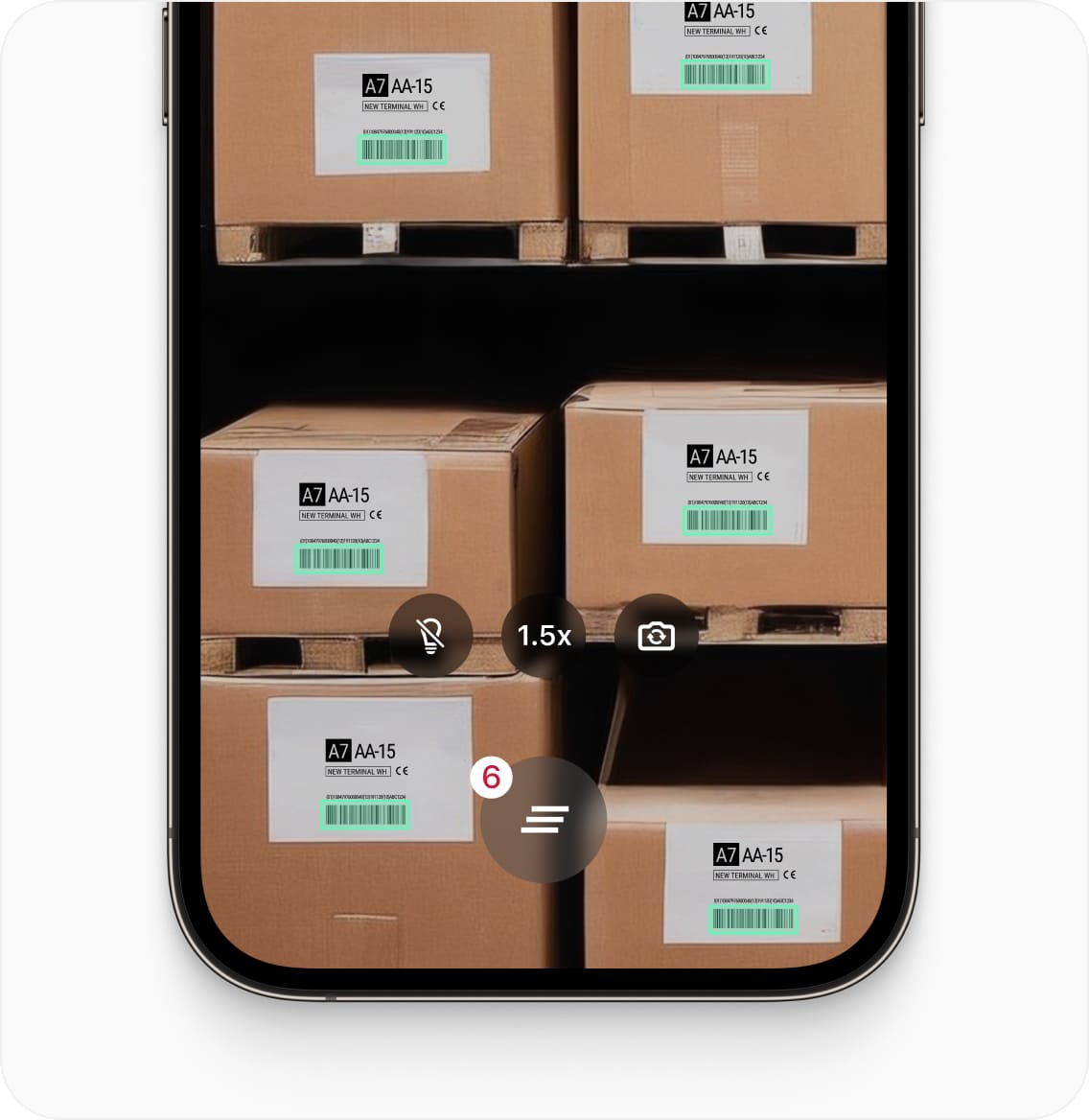

- Multi-Scanning: Scan multiple barcodes simultaneously. Warehouse workers can scan a whole batch of items with just one scan, speeding up the pick-by-scan scanning process.

- Scan & Count: Helps warehouse workers count multiple items in one go, ideal for confirming that the right amount of items was picked after completing a pick list.

Do you want to learn more about this all-round solution for warehouses? Try the Scanbot Barcode Scanner SDK in our free web or mobile demo app. If you are ready to try out the SDK for your project, get a free 7-day trial license here.