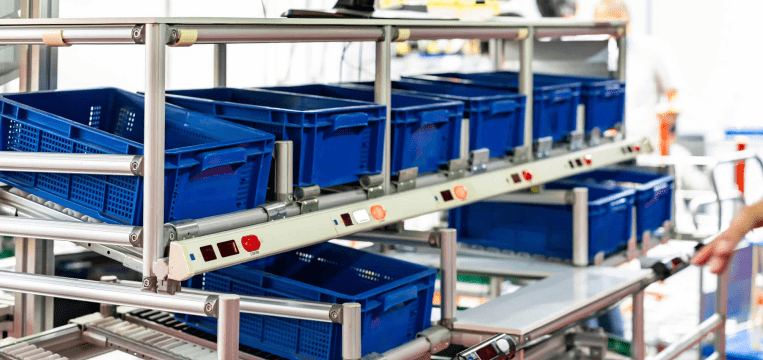

What is cycle counting?

Cycle counting is an inventory management technique that involves regularly counting a small portion of inventory throughout the year, rather than conducting a full physical inventory count annually. This method allows businesses to maintain accurate inventory records continuously while minimizing disturbances to daily operations.

Unlike traditional annual physical counts, cycle counting can be performed during normal business hours without significant interruptions. It provides a more efficient and accurate way to track inventory levels in real-time.

Now that we understand what cycle counting is, let’s explore why it’s superior to traditional inventory management methods.

Advantages of cycle counting

Cycle counting offers several significant advantages over traditional annual inventory counts:

- Increased accuracy: By counting inventory more frequently, discrepancies can be identified and corrected quickly, leading to more reliable inventory data.

- Improved flexibility: Businesses can set schedules for counting specific items or areas of the warehouse at different intervals, allowing for a more tailored approach to inventory management.

- Time and cost savings: Regular cycle counts eliminate the need for a large-scale annual inventory count, saving valuable time and reducing associated costs.

- Real-time inventory tracking: Cycle counting provides up-to-date information on inventory levels, allowing for better decision-making and more responsive supply chain management.

- Early problem detection: Regular counts help identify issues such as theft, damage, or misplacement of items more quickly, allowing for prompt corrective action.

- Reduced operational disruptions: Unlike full physical counts, cycle counting can be performed without halting regular business activities.

These advantages make cycle counting a superior inventory management technique compared to traditional methods, offering businesses a more efficient and accurate way to track their inventory.

While cycle counting itself is beneficial, combining it with modern technology can take your inventory management to the next level. Let’s see how barcode scanning enhances the cycle counting process.

How barcode scanning improves cycle counting

Incorporating barcode scanning technology into cycle counting processes significantly enhances the efficiency and accuracy of the process:

- Increased speed and efficiency: Barcode scanners allow for quick and easy item identification and counting, reducing the time required for inventory checks.

- Improved accuracy: By eliminating manual data entry, barcode scanning significantly reduces human errors in the counting process, leading to more reliable inventory data.

- Real-time data updates: When integrated with a Warehouse Management System (WMS), barcode scanners can update inventory records instantly, providing real-time visibility into stock levels.

- Automated data collection: Barcode scanning automates the data collection process, eliminating the need for paper-based counting and manual data entry, which are time-consuming and prone to errors.

- Enhanced inventory control: The combination of cycle counting and barcode scanning allows for more frequent and accurate inventory checks, leading to better overall inventory management and control.

Barcode scanning clearly improves the cycle counting process, but the software behind it offers even more benefits. Let’s explore how barcode scanning software can further optimize your inventory management.

Benefits of using barcode scanning software

Implementing barcode scanning software as part of your cycle counting process offers additional advantages:

- Seamless integration: Barcode scanning software can easily integrate with existing barcode inventory management systems, providing a unified solution for tracking and managing inventory.

- Data analysis and reporting: Advanced software solutions offer robust reporting and analytics capabilities, helping businesses gain valuable insights from their inventory data.

- Mobile accessibility: Many barcode scanning software solutions are compatible with mobile devices, allowing for greater flexibility in conducting cycle counts throughout the warehouse.

- Customizable workflows: Software solutions often allow businesses to customize their cycle counting processes to fit their specific needs and requirements.

- Improved traceability: Barcode scanning software can help track the movement of items throughout the supply chain, enhancing overall inventory visibility and traceability.

Choosing the right barcode scanning software is crucial: With advanced features like multi-scanning and AR overlays, the cycle counting process can be streamlined even further. By integrating an SDK into their existing mobile apps, businesses can transform their workers’ smartphones into multi-tools and seamlessly integrate barcode scanning features with other key functionalities.

That’s exactly what the Scanbot Barcode Scanner SDK offers. Its quick and reliable barcode scanning features can be integrated into any iOS, Android, Windows, Linux, or Web app, helping companies reduce costs by eliminating slow and error-prone manual data entry.

The SDK supports multiple barcode scanning use cases, which makes it easier to adapt tits functionalities to a company’s specific needs:

- Single Scanning: Ideal for simple activities where only a single barcode needs to be scanned, such as re-ordering a product or a stock lookup.

- Batch Scanning: This feature allows users to scan multiple codes in succession without closing the scanning screen. This simplifies tasks where a series of barcodes must be scanned, such as picking several products for one order.

- Multi Scanning: Captures multiple barcodes simultaneously. For example, it enables logistics workers to scan several packages at once.

- Find & Pick: Given one or more barcode values, the SDK will visually highlight and scan the correct items for the user. This simplifies finding the right package in last-mile operations, for example.

- Scan & Count: Lets users count multiple items automatically in one go. This allows retail workers, for example, to complete inventory counting more quickly.

Let’s take a look at how one of our clients successfully implemented this technology.

Case study: Cypher Robotics

Cypher Robotics, a company specializing in automated inventory management solutions, provides an excellent example of how barcode scanning technology can revolutionize cycle counting processes.

Challenge and solution

Cypher Robotics needed a versatile, reliable, and efficient barcode scanning solution for their cycle counting systems. They chose the Scanbot Barcode Scanner SDK for Linux systems due to its compatibility with various operating systems and processor architectures, making it adaptable to diverse hardware configurations.

Key benefits

- Offline Functionality: The SDK’s ability to work fully offline allowed Cypher Robotics to run the system locally on their cycle counting machines. This eliminated latency issues and enabled swift task execution, particularly beneficial in facilities without WiFi.

- Quick Implementation: The initial testing phase took only one week, with full implementation completed in less than two weeks. This rapid integration, including troubleshooting, demonstrated the SDK’s user-friendly nature.

- Technical Support: Throughout the implementation, Scanbot SDK provided technical assistance, even writing a custom barcode generator for Cypher Robotics’ client.

- Accuracy and Automation: By showcasing the accuracy of their Scanbot SDK-powered systems, Cypher Robotics demonstrated that tasks like cycle counting could be fully automated, ensuring error-free inventory management.

- Easy Demonstration: The SDK’s mobile version allowed Cypher Robotics to easily demonstrate its capabilities using just a smartphone, making its value clear to clients of any technical background.

Results

Implementing the Scanbot Barcode Scanner SDK allowed Cypher Robotics to offer a highly accurate, efficient, and easy-to-use cycle counting solution. This not only improved inventory management for their clients but also freed up skilled workers to focus on more strategic tasks within their organizations.

Conclusion

Cycle counting, especially when combined with barcode scanning technology, represents a significant leap forward in inventory management practices. By adopting this approach, businesses can enjoy increased accuracy, improved efficiency, and real-time visibility into their inventory levels.

The advantages of cycle counting, coupled with the precision and speed of barcode scanning, make this method superior to traditional inventory management techniques. Not only does it save time and reduce costs, but it also provides businesses with the agility and accuracy needed to thrive in today’s fast-paced business environment.

By implementing cycle counting with barcode scanning technology like the Scanbot SDK, businesses can significantly improve their inventory accuracy, reduce operational costs, and maintain a more efficient warehouse management system. This powerful combination is the key to staying competitive and maximizing profitability in an increasingly complex supply chain landscape.